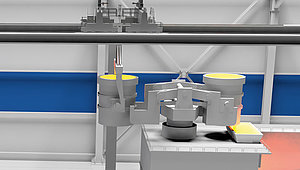

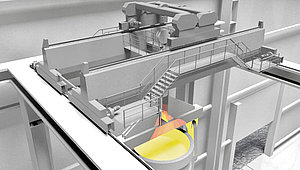

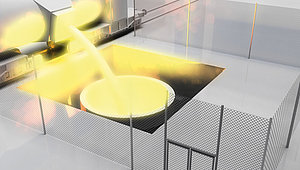

Metal production

Switchgear from Schmersal is used in the entire heavy industry. The different basic designs are suitable for extended temperature ranges and high mechanical stresses. They can be combined with a large range of actuators, contact variants and contact configurations. Adjustable switching points and a comprehensive program of accessories provide for an additional extension of the application range.

The result: highly reliable heavy-duty switchgear, which stand the test for decennia under rough operating conditions - in the entire process chain of the steel industry as well as in other sectors of metal processing.