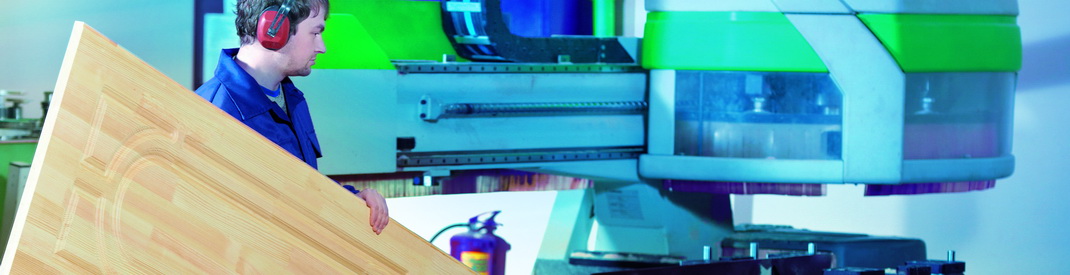

Wood

Wood is a popular natural material, both in carpentry and in architecture. The processing methods "from forest to furniture" are manifold. They include debarking and sawing as well as miscellaneous surface treatments, furniture assembly, and strand board production methods. Most of these methods and processes have a common feature, i.e. they entail hazards and risks for the operators.

In ancient times, sawmills were a downright synonymous with high injury-risk workplaces. This situation has changed since then - not in the least as a result of the ever stringent regulations with regard to machine safety and the higher level of automation.