Consistent global standards

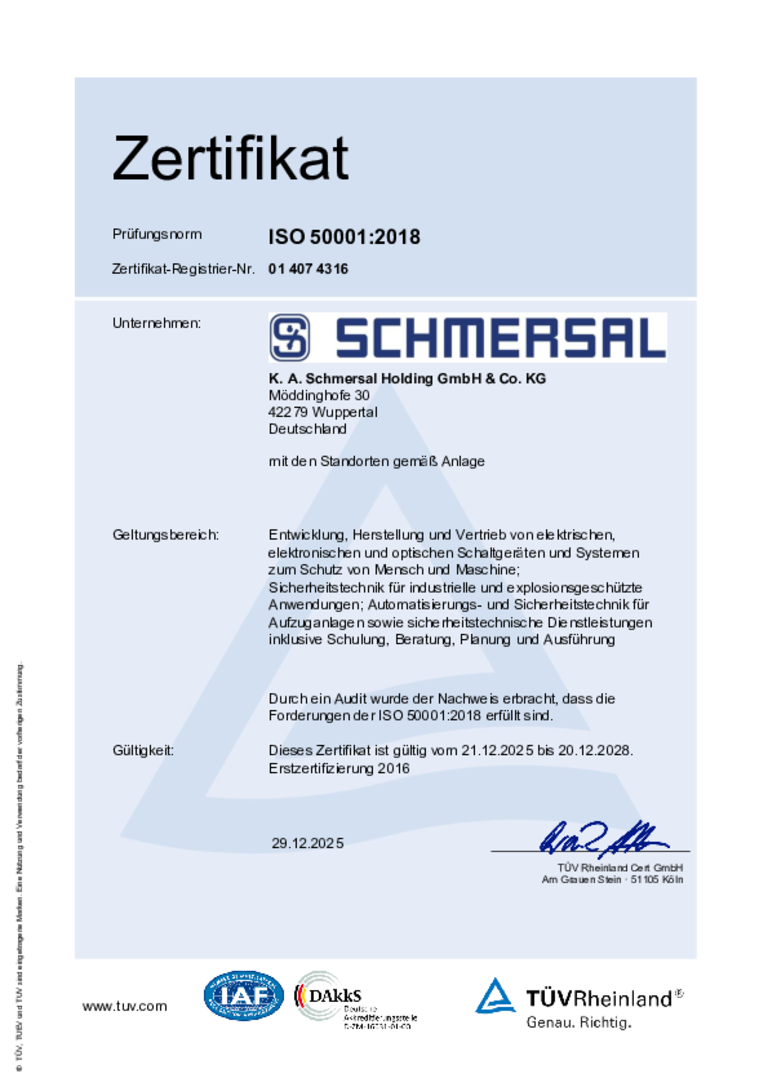

All production subsidiaries of the Schmersal Group work on the basis of a quality management system which is certified in accordance with DIN EN ISO 9001. The QM system is modular in design and sets out clear rules for all processes and workflows within the company.

The cross-site validity of quality rules goes way beyond the structure of the management system. For all national and international sites, the standards are largely dependent and consistent processes and tools are used. The processes are coordinated on a global basis to achieve and guarantee maximum transparency and effectiveness.

Of course, our customers receive switchgear in line with the requisite national certifications, e.g. CCC (China), UL/CSA (North America) and UKCA (United Kingdom).

Qualification in our own accredited test laboratory

The well-equipped Schmersal laboratory at the Wuppertal site is recognised by DAkks, the German accreditation body, and accredited in line with DIN EN ISO/IEC 17025. This means it can take responsibility for qualifying low-voltage switchgear based on the requirements of applicable international standards.

For the customers of the Schmersal Group, this means: new devices and technologies can be checked and launched onto the market quicker and more cost-effectively. Time-consuming third-party inspections are simplified, customer-specific requirements of the scope of testing can also be implemented more easily.

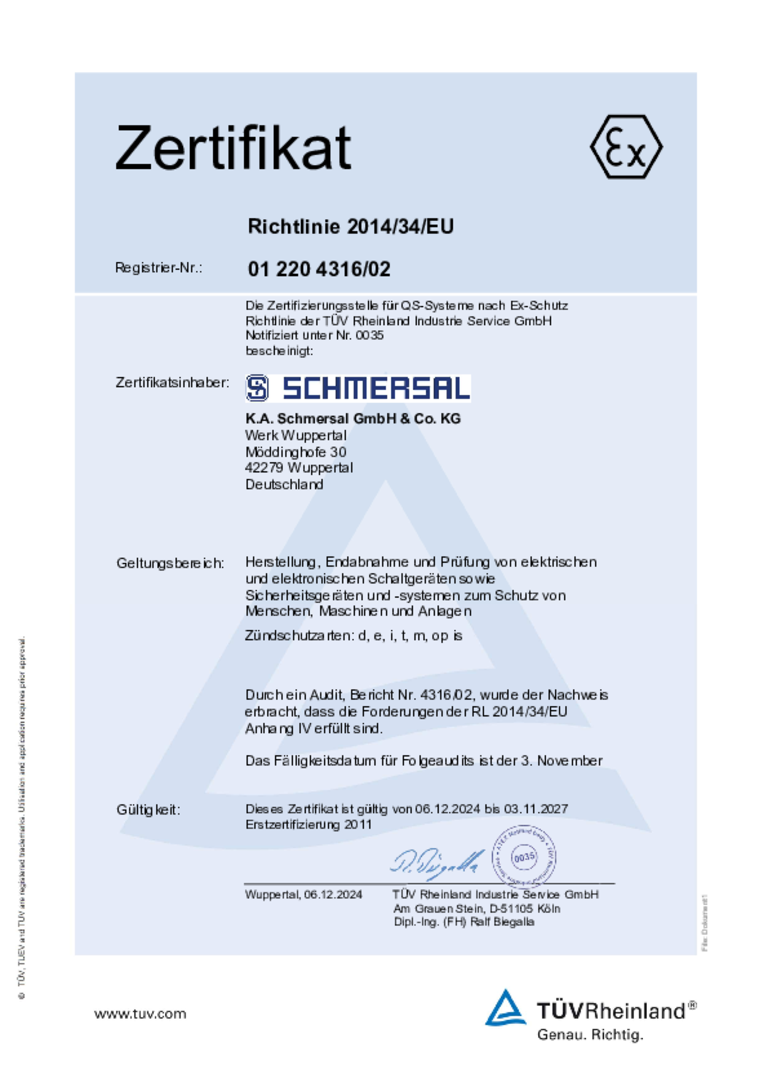

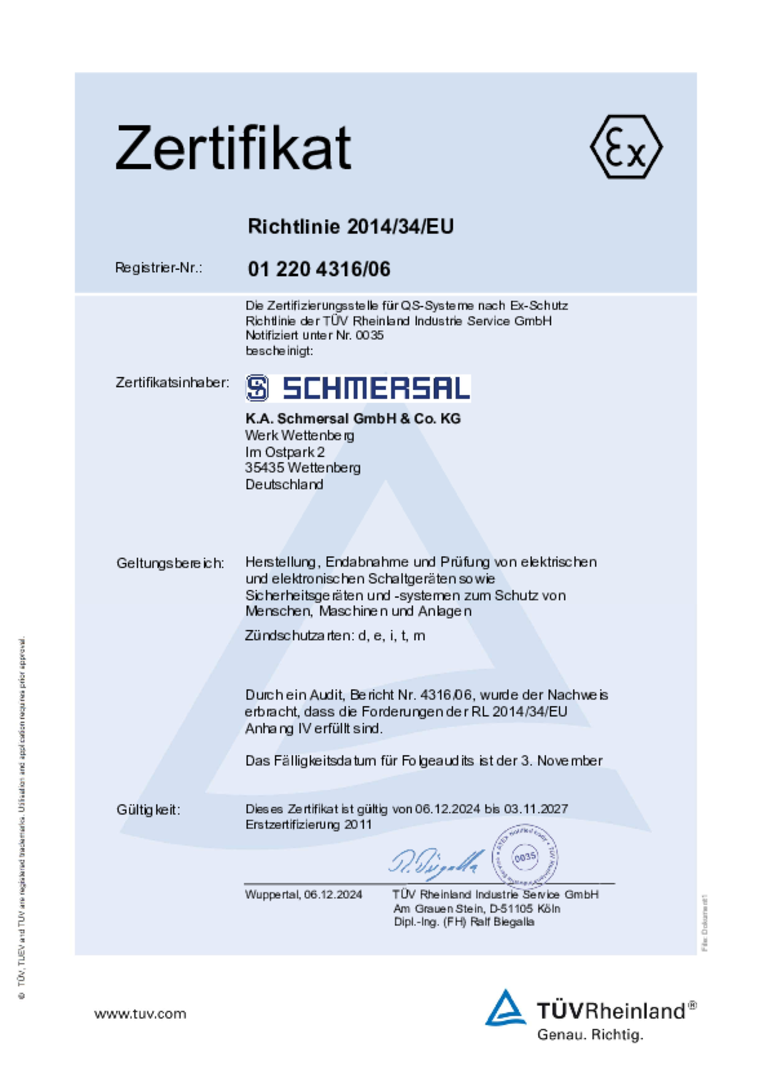

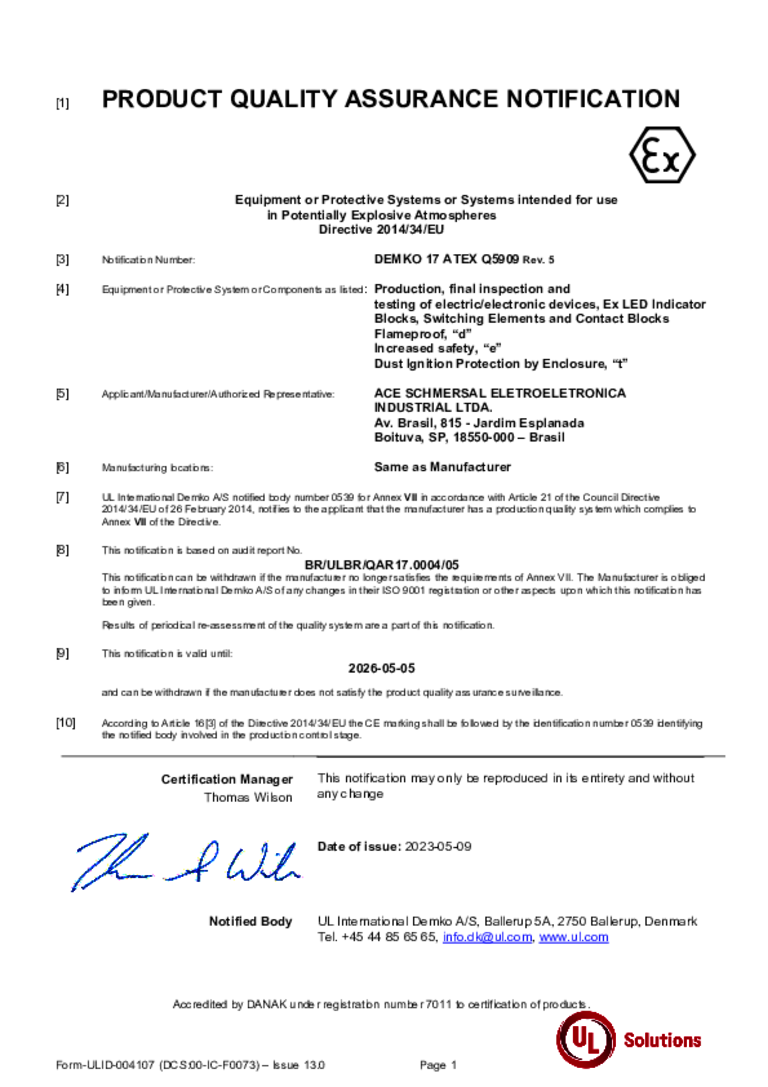

For ex-switchgear

All Schmersal Group sites developing and producing switchgear for explosion-protected applications also have certification in accordance with DIN EN ISO 9001, which stipulates certification and approvals for the QM system based on the applicable guidelines and standards. This is another feature of the high quality standards of the Schmersal Group. This guarantees the requisite safety in the very sensitive area of (safety) switchgear for explosion-risk environments.

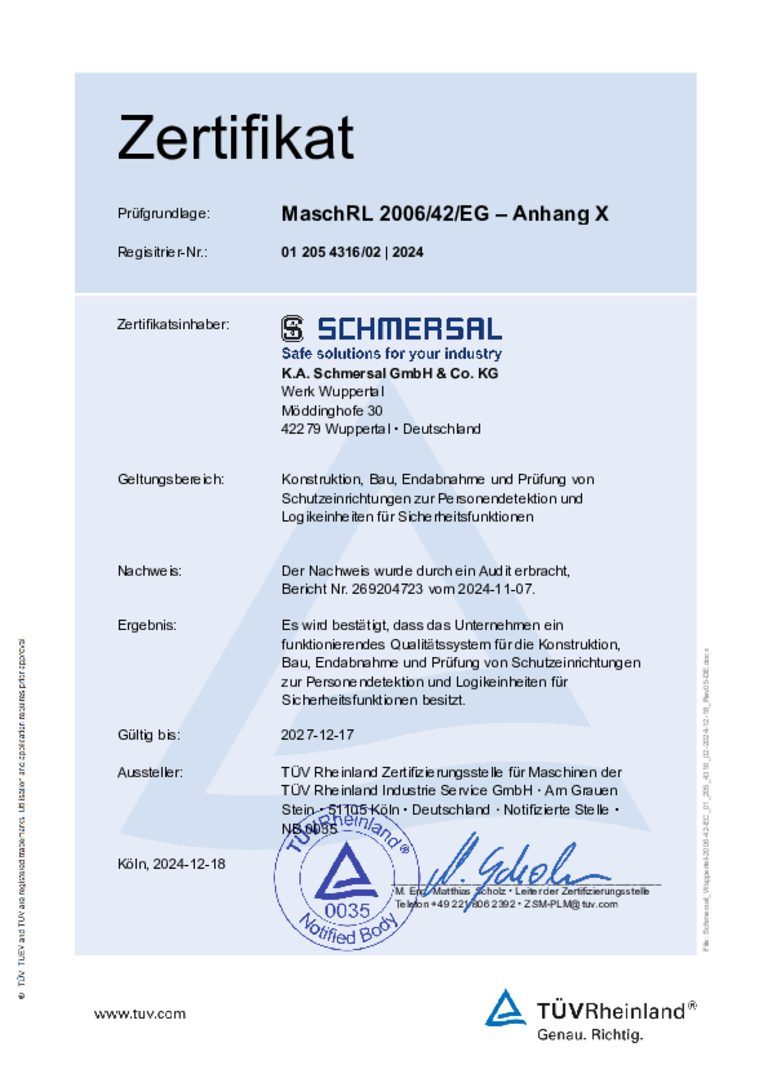

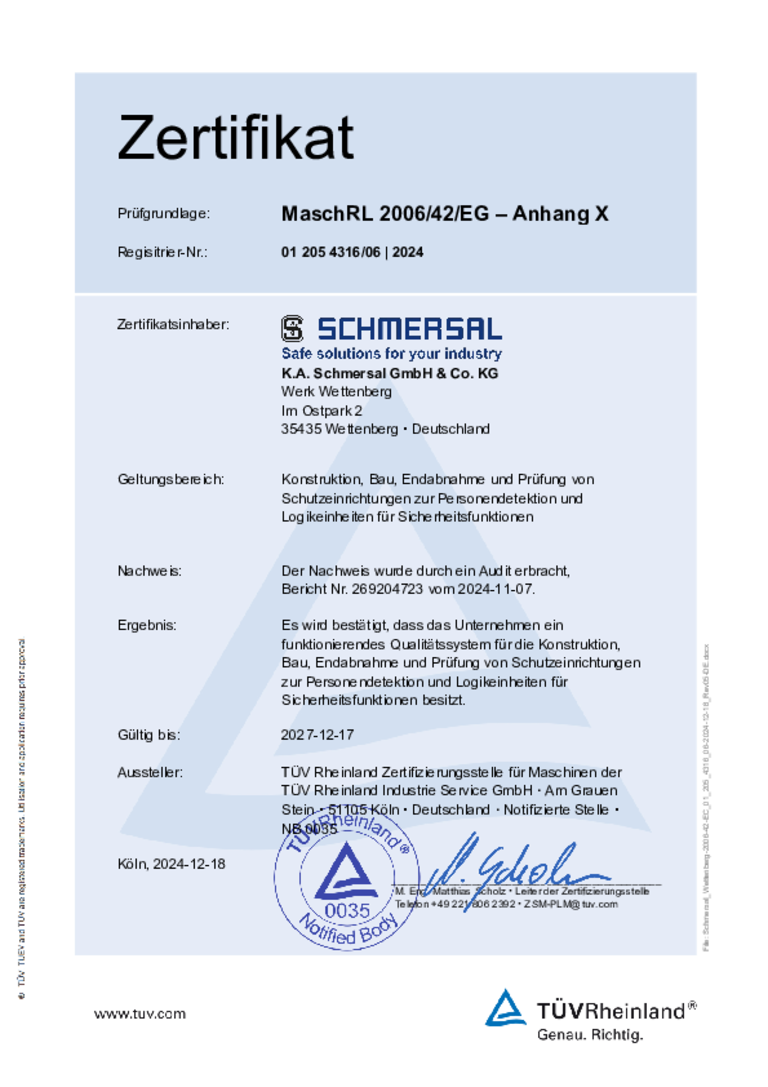

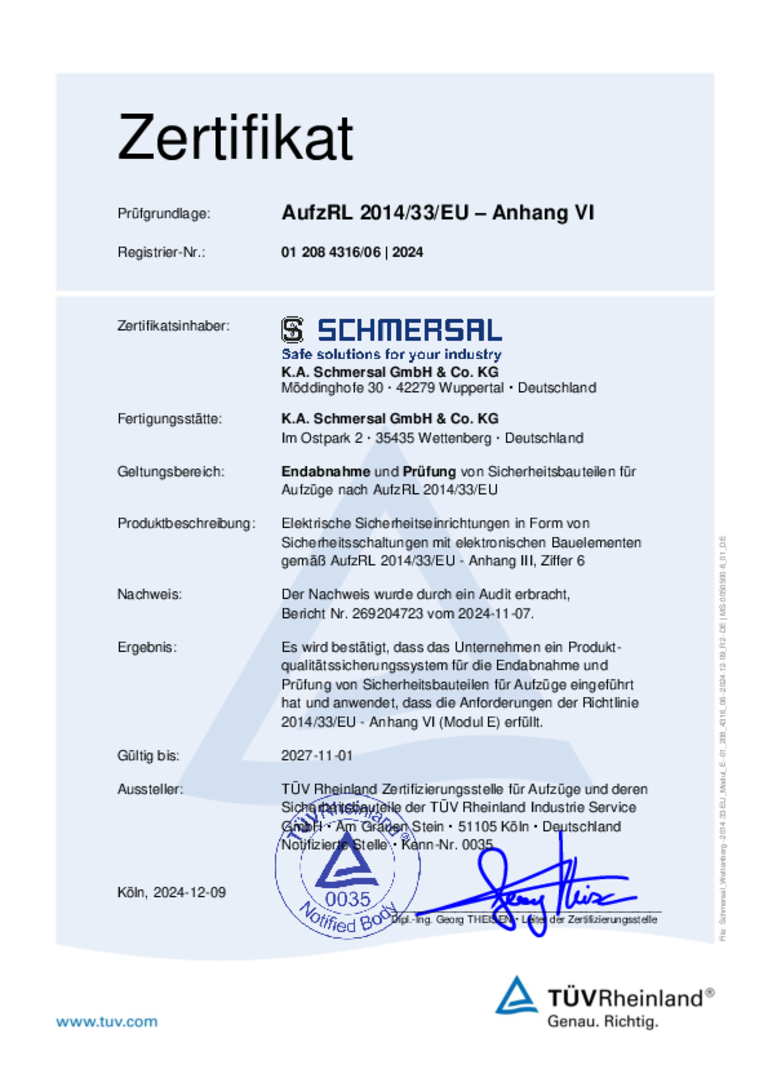

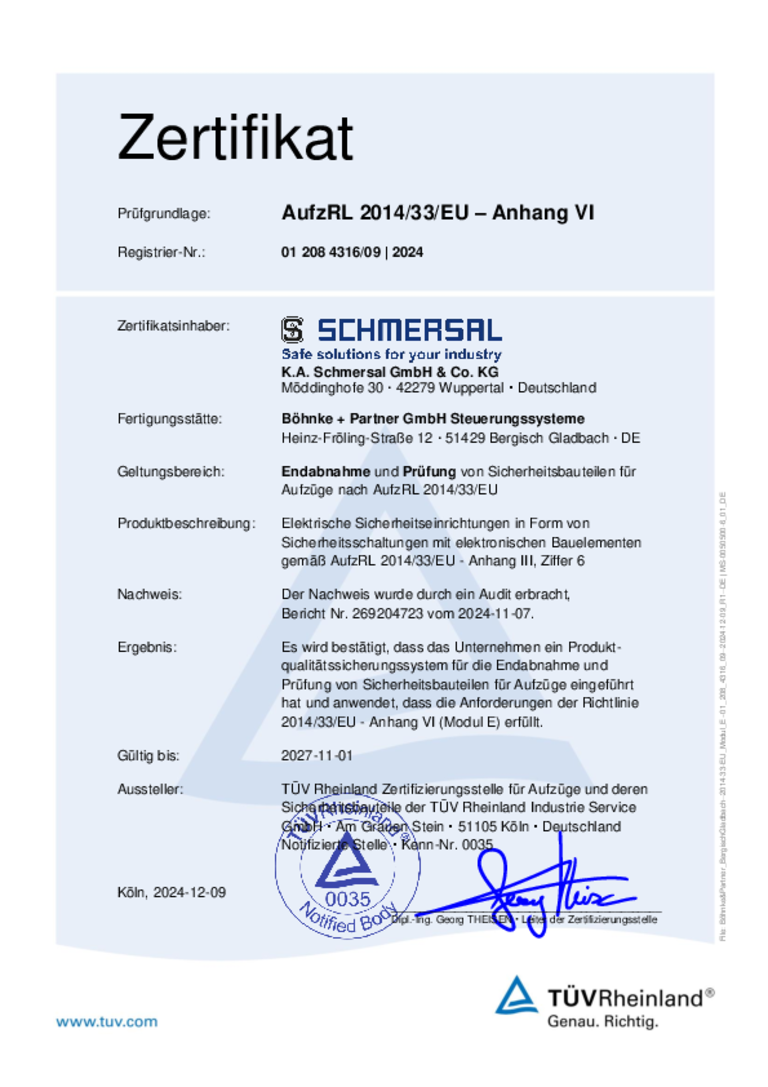

Certification in accordance with Appendix X MD

Certification in accordance with Appendix X of the Machinery Directive (“Comprehensive Quality Assurance”) at the Wuppertal and Wettenberg sites means that we can develop, test and release our own machine safety components. At the same time, it confirms the high quality level and expertise of the sites.

Exacting quality standards for testing and certification

The Schmersal test laboratory currently employs eleven people, of which nine are officially registered testers. The test equipment includes test panels for electrical and mechanical rigidity and service life testing, environment simulation systems (temperature, humidity, vibration, seals) and the necessary EMC equipment.

As well as testing during development and type-testing new safety switchgear, the lab’s responsibilities also include securing series production and testing and (in cooperation with the developers) optimisation of existing ranges. A separate quality management system which is fully integrated into the Schmersal Group QM system guarantees compliance with exacting quality standards in testing and qualification.

DIN EN ISO 9001

Main certificate including attachment for all production sites:

English