STANDSTILL MONITOR

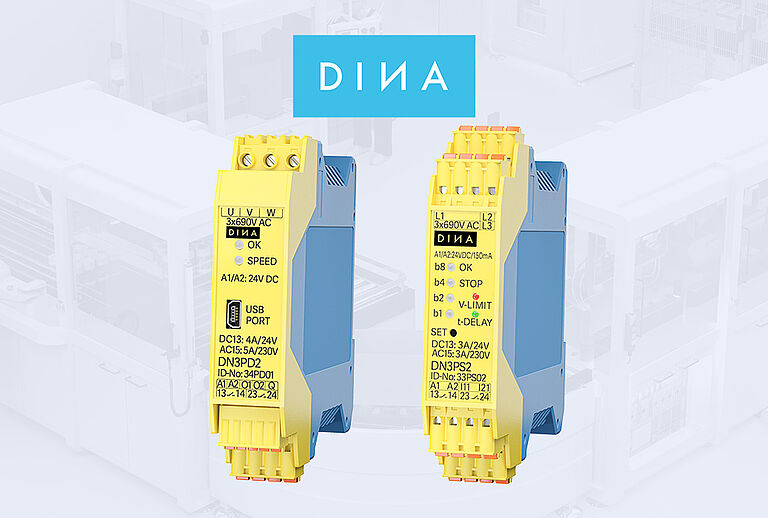

DN3PS2/33PS02

- 3-phase Back EMF monitoring

- Simple wiring

- Requires no external sensors

- Rated up to 600V AC

- Time delayed outputs possible

- 22.5mm housing

- PLe / Category 4

SAFE DRIVE MONITOR

DN3PD2/34PD10

- Monitoring of safe motion via the frequency of the rotating field of the motor

- Space-saving, no encoder required

- Simple parameterization via GO:BEYOND Software tool

- Time delay outputs possible

- Adjustable speed from 0 to 1200 Hz

- PLe / Category 4

Rotational Direction monitor

DN3PR1/33PR01

- Direction monitoring of 3-phase motors

- Space-saving, no encoder required

- No parameterization necessary

- 2 Relay output

- 2 Diagnostic output

- PLe / Category 4

Reference materials for download

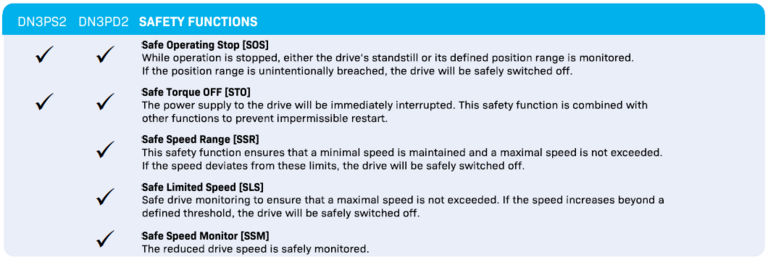

THE FUTURE OF SAFE SPEED MONITORING

This whitepaper from DINA Elektronik, provides an overview of safe speed monitoring, defining the various safety functions such as Safe Limited Speed (SLS) and Safe Torque Off (STO). It also highlights the advantages of DINA’s sensorless monitoring system with some real-world applications.

Sensorless Standstill Monitoring

This whitepaper explores sensorless standstill monitoring—a cost-effective, reliable safety solution for industrial machinery. Learn how it works, its advantages over sensor-based systems, and where it’s applied. Essential for engineers and safety managers seeking compliance, reduced costs, and robust performance in automated environments.

Product presentation

Boosting Safety And Efficiency In Sensorless Drive Monitoring

In this session we spoke with guests from DINA Elektronik to discuss how their innovative sensorless safety monitoring solutions are transforming machine safety in industrial automation.

Introduction

About DINA Elektronik

How Sensorless Drive Monitoring Works

Benefits of sensorless drive monitoring

DINA drive monitors

GO:BEYOND software demo

Application stories

Summary-Key takeaways