Unique features of the Safety Fieldbox from Schmersal include the need for just a single M12 slot for solenoid interlocks and safety light curtains and the connection of control panels with EMERGENCY STOP function and up to three non-safe command and signalling devices.

Connecting safety devices via the Safety Fieldbox also helps to save costs, as up to eight devices can be connected to a single Fieldbox, which is much more cost-effective than equipping each individual device with a bus interface.

An integrated digital input on each device slot allows the diagnostic signals of all connected safety devices to be evaluated. This means that safety-related and operational signals, such as those required for diagnostic purposes, can be collected and transmitted. The user can use this information to detect irregularities, e.g. a safety guard that has been moved, and enable prompt intervention if service is deemed necessary. This helps to improve system availability and minimise the risk of downtime. Users can also benefit from greatly simplified, and therefore more cost-effective, wiring of safety devices.

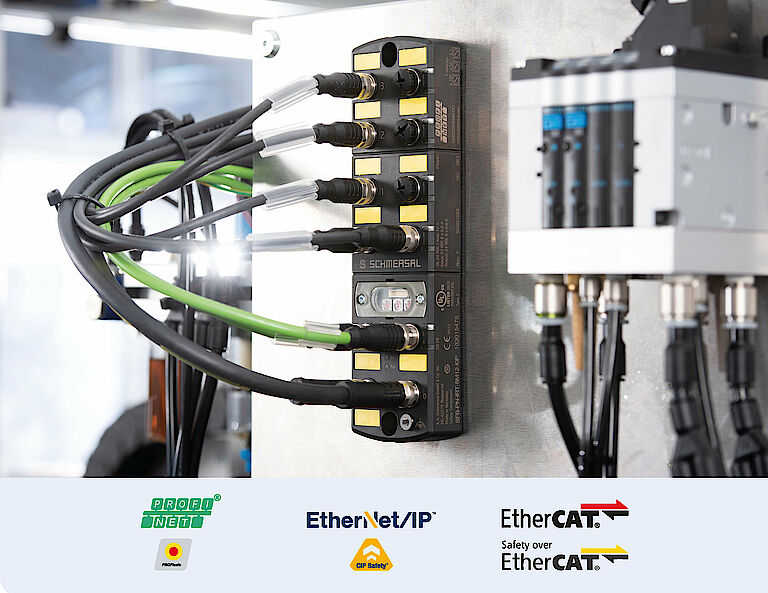

Safety Field Box in three versions:

SFB-EIP-8M12-IOP

for EtherNet/IP with CIP-Safety

SFB-PN-IRT-8M12-IOP-V2

for PROFINET/PROFIsafe

SFB-EC-8M12-IOP

for EtherCAT with FSoE

and ctrlX World compatible

SFB Pre-wired connecting cables

Find all the compatible cables for your SFB plug and play connections:

M12- pre-wired power cable

M12-Power connecting cables

M12-IE Pre-wired cable

M12-IE Connecting cables

M12-8 pole connecting cables

Special Field Box Compatable devices

All common types of safety switchgear with eight-pin M12 connector enables can be connected. Here are a few special versions specifically designed to be compatible:

BDF 200-FB Control Panel

AZM 161-FB Solenoid lock

AZM 170-FB Solenoid lock

AZ 16-FB Keyed interlock

System Engineering Tool

Schmersal’s web-based System Engineering Tool makes planning safety switchgear installations simple and efficient.

Select from multiple installation options, including the SFB Safety Field box. Build your system with intuitive drag-and-drop functionality. Easily adjust cable lengths and let the tool automatically alert you to any low-voltage issues. When your design is complete, you’ll receive a comprehensive parts list, including distributor components, connection cables, and devices.

Start designing your system today: www.system-engineering-tool.com