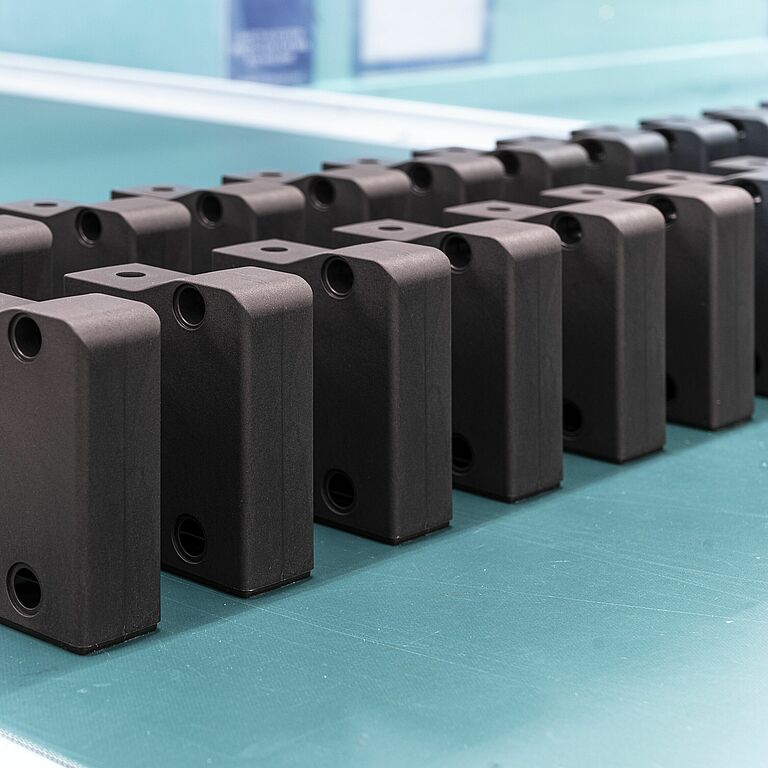

Wuppertal, 13 May 2024. The Schmersal Group is planning to use recycled material in the production of safety switches with plastic housings in future. ‘Our aim is to use 20 per cent recycled material in the switches manufactured using the injection moulding process,’ says Matthias Banaszek, Head of Value Management / Innovation Manager at Schmersal. The first independent analyses now show that Schmersal is well on the way to achieving this goal. The project is part of Schmersal's sustainability strategy with the aim of reducing its CO2 footprint.

To ensure that the recycled material used has no influence on the quality of the safety functions, Schmersal commissioned comparative tests at the Lüdenscheid Plastics Institute. Switches made purely from virgin material were tested in comparison with switches consisting of 80 per cent virgin material and 20 per cent recycled pellets. Three different plastic materials were tested: Ultramid, Hostaform and Frianyl. The results from the Lüdenscheid Plastics Institute are now available: Regranulates made from Ultramid and Hostaform could be used immediately, while further product-related tests are required for Frianyl.

As part of the comparative tests, the Kunststoff-Institut Lüdenscheid examined a number of parameters using standardised test methods, such as the Charpy impact test to DIN EN ISO 179-1, which is used to determine the ductility (or toughness) of a plastic. Or the density measurement according to DIN EN ISO 1183-1 and the contact resistance test according to IEC 60093 to describe the electrical insulation behaviour. The aim was to prove that switches made from mixed materials can withstand adverse environmental conditions just as well as those made from pure new materials. This has been demonstrated for two materials.

The next step is TÜV certification of the safety switches. This will pave the way for series production of the switches with recycled pellets. Schmersal would then be the first manufacturer to use recycled material in safety switches.