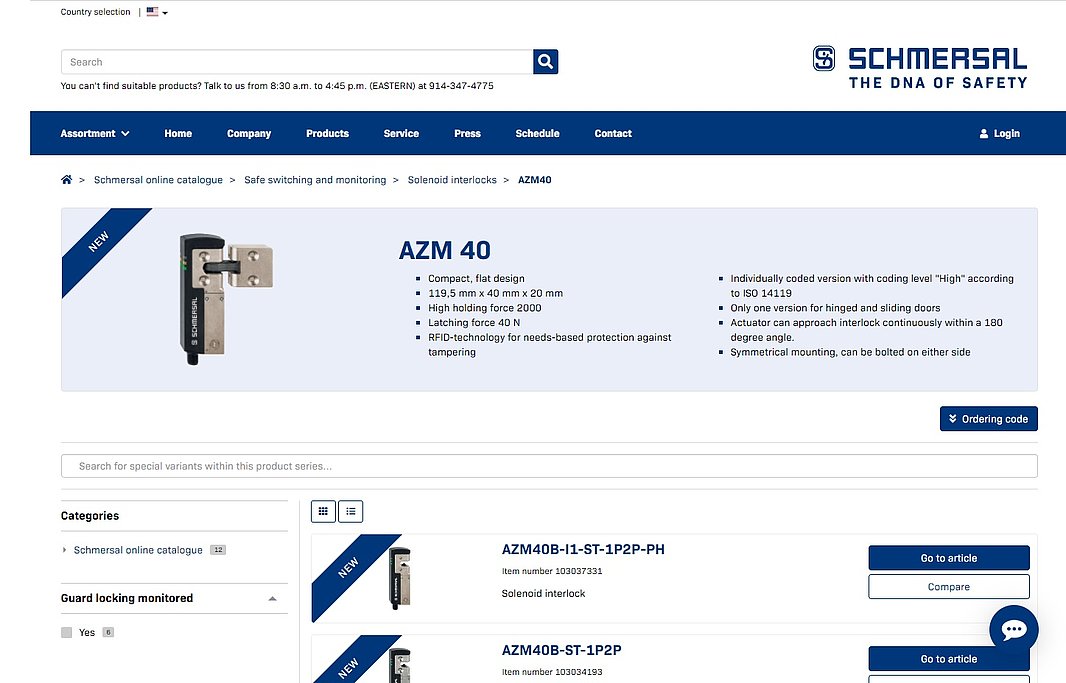

The AZM40 is a safety rated solenoid interlock with an integrated radio frequency identification (RFID) based electronic safety sensor.

The AZM40 Series is designed for machine/work cells where access to a hazardous work area must be controlled until safe conditions exist. The solenoid lock provides 2000 N to secure the machine guard until dangerous conditions, which may exist immediately after removal of power, have abated. The solenoid lock may be controlled by a time delay, motion detector, position sensor or other suitable component.

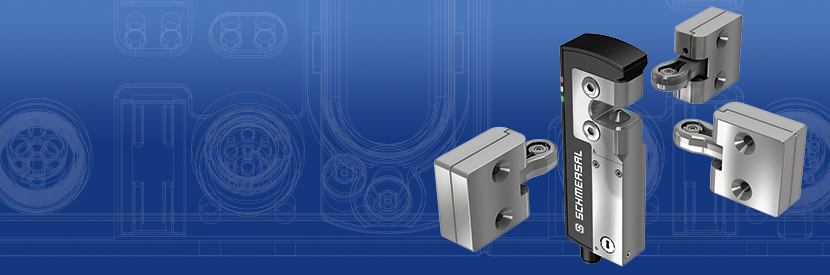

The housing is amazingly compact: 40 x 119 x 20 mm. The mounting holes are placed centrally in the housing, to match the channel in typical extruded profiles used in guard doors. We offer two types of finishes for the screw bore holes: countersunk or flat. The countersunk holes are tapered at 45° and allow for the screws to rest flush with the housing. The flat finish (PH) allows the flat headed screws to protrude.

The AZM40 works on the bistable principle: In the event of a power cut, it retains the current position. This ensures safe operation, whatever the status of the machine. Even if there are hazardous run-on movements, the safety door remains safely locked in the event of a power failure. Another advantage of the bistable principle is the consistently low energy consumption, as the interlock only requires power when the door is to be locked or unlocked.

The inclusion of the RFID sensor offers the option of individual coding: The basic version of the RFID sensor responds to any AZM40 target actuator; The “I1” version only accepts the coded ID number of the specific target actuator which is taught in during the first start-up; The “I2” version allows the teach-in process to be repeated, allowing replacement of a lost or damaged actuator, with a 10 minute delay with the teaching process.

Applications for personnel protection (interlock monitored), the safety outputs are switched on when the safety door is closed and the interlock locked. The AZM40B model (actuator monitored) can be used in applications for process protection. In this variant, the safety outputs are actuated as soon as the safety door is closed. With this device, locking the interlock is not absolutely necessary.

The AZM40 series is compliant with North American and International standards such as cULus and CE. It’s two-channel input signal meets PLe/Category4 (ISO 13849) or SIL3 (IEC 61508) for both its interlock and guard locking function. It is a Type 4 interlock per ISO 14119, with a high coding level with the individual coding option (I1 or I2). It has an IP69 rating, suitable for high temperature and high pressure washdown applications

Contact us for more information with our CONTACT FORM