Engineering Safety Control Measures — Best Practices for a Safer Workplace

The Executive Summary from our webinar

Discover how engineering controls play a pivotal role in protecting workers by isolating hazards, and explore effective solutions, standards, and often-overlooked safety aspects across industries.

Download

the summary

View

webinar

Basic OSHA Requirements for a Control Reliable Safety Circuit

The Executive Summary from our webinar

Control reliability is a benchmark for the design of safety control circuits. Properly designed control circuits ensure the safety of the system overall. We review the basic wiring designs of a safety circuits, to help you fulfill OSHA requirements and meet the conditions of specific Performance Levels (PL) and Safety Integrity Levels (SIL).

Download

the summary

View

webinar

SAFER Workplace

The SAFER Workplace initiative promotes workplace safety to reduce the potential of near misses, accidents, and injuries.

The SAFER acronym is based on the 5 fundamental steps used to conduct a risk assessment and stands for STOP, ASSESS, FORMULATE, EXECUTE, and REVIEW. These steps are fundamental to properly addressing any concerns such as unsafe operations of machinery so that a safe and efficient solution can be created and implemented

Download

the article

National SAFER Workplace Day - Friday, June 28, 2024

The colour makes the difference

New Door handle system DHS

Door handle systems should be safe and ergonomic. If they are also easy to install and offer a high level of transparency at the human-machine interface, the user has everything in view and under control.

Author: Stephan Frick, Deputy Head of Product Management, Schmersal Group, Wuppertal, Germany

Source: DER KONSTRUKTEUR 2024/06 www.derkonstrukteur.de

Download

technical article

Selection Guidelines For Safety Light Curtains

The four main options to consider in selecting the right Safety Light Curtain for your application.

Safety light curtains are a viable safeguarding option for point of operation or perimeter guarding. Choosing the right one is not terribly complicated, once a thorough risk assessment is performed. It helps to define the Type, Resolution, Protection field, and Special operation modes needed for your application.

Download

technical article

Minimum Distances for Safety Control Measures

The executive summary from our webinar

Fixed guards and presence sensing safety devices are often used as control measures for risk reductions. Discover the crucial factors behind implementing these measures - particularly the considerations for their strategic placement to ensure compliance and effectiveness in risk reduction. In this webinar you will master the art of calculating and implementing minimum safe distances

Download

the summary

View

webinar

TIME-OF-FLIGHT CAMERA FOR AUTOMATION TECHNOLOGY

3D view of intralogistics processes

A 3D camera expands the options offered by sensor systems in intralogistics by another dimension. This allows the camera to offer precise real-time capture of fill levels or a comprehensive view of the process. In addition, it can also be used as the ‘eye’ of IIoT applications, allowing it to determine KPIs such as ‘Overall Equipment Efficiency’ (OEE).

Source: Technische Logistik 11/23, HUSS-MEDIEN GmbH

Author: Katrin Wirz, product manager, Schmersal Group

Download

technical article

EVALUATION OF OPERATIONAL AND SAFETY-ORIENTED SIGNALS

In focus: the safety of machinery and connectivity

New gateway, new Safety Fieldbox and a new 3D camera – just some of the exhibits that Schmersal will be showcasing at SPS. All three components will be live demonstrated in an IIoT demonstrator to highlight the practical bene-fits that continuous connectivity has to offer – especially in terms of the safety of machinery.

Source: GIT SICHERHEIT 11/2023, Wiley-VCH GmbH, Weinheim

Author: Volker Heinzer, product manager for programmable electronic systems and Industry 4.0/IIoT,Schmersal Group

Download

technical article

THE SAFETY OF MACHINERY – CONNECTIVITY IS WHAT MAKES THE DIFFERENCE

New networking concepts - no need for wiring

Integration, networking and linking are important trends in automation technolo-gy. Both a machine’s manufacturer and user can reap the benefits of digitisation, such as increased productivity, easy adaptation to individual requirements and improved error diagnosis. The Schmersal Group will be showcasing innovations in safety-oriented networking at SPS.

Source: Trade magazine DER KONSTRUKTEUR, issue 2023/10

Author: Tobias Thiesmann, Manager Systems and Solutions, Schmersal Group

Download

technical article

HERE’S TO POSITIVE COOPERATION!

Planning and construction of a collaborative robot cell

Safe collaboration between humans and robots in collaborative work systems is both possible and offers clear benefits, including in packaging processes. There are, however, a number of prerequisites that need to be satisfied, and several machinery safety standards that must be taken into consideration

Source: Trade magazine LVT LEBENSMITTEL Industrie 10 • 2023

Author: Benjamin Bottler M.Sc., Safety Consultant, Schmersal Group

Download

technical article

Applying ISO 13849 Functional Safety to Machines in the USA

The executive summary from our webinar

Functional safety and Performance Levels are key elements behind the global-harmonized machine safety standard ISO 13849. This webinar provided an overview of the standard, when and how to use it, how it relates to machine safety in the USA and a look at misconceptions surrounding the standard.

Download

the summary

View

webinar (YouTube)

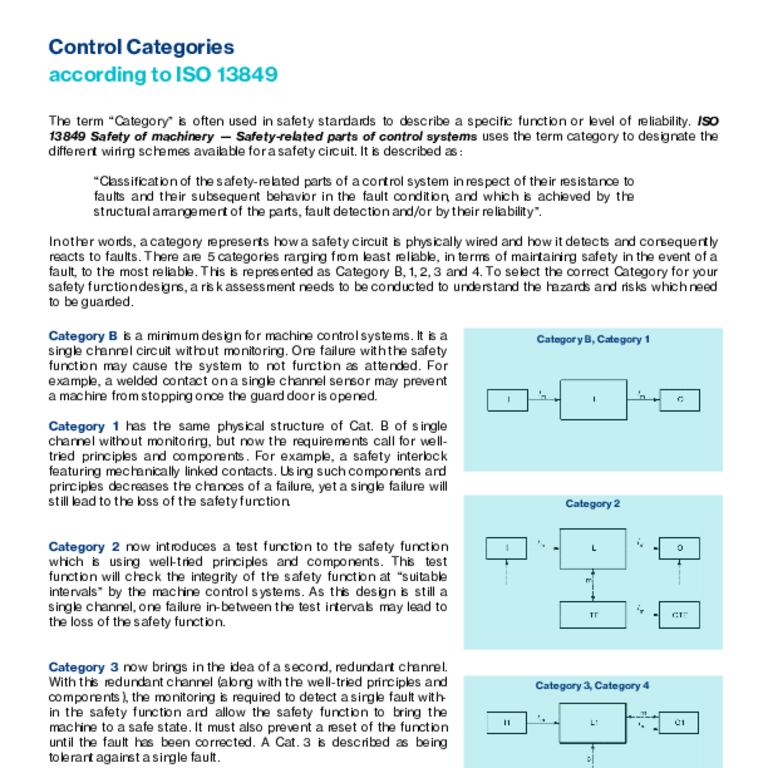

Control Categories according to ISO 13849

The term “Category” is often used in safety standards to describe a specific function or level of reliability.

ISO 13849 Safety of machinery — Safety-related parts of control systems uses the term category to designate 5 different wiring schemes available for a safety circuit. This paper briefly explains these categories.

Download

technical article

Commonly Overlooked And Misapplied Machine Safety Requirements

The executive summary from our webinar

With so many safety aspects to consider, it is easy to overlook crucial elements to successfully implement a safety measure. Some commonly overlooked and misapplied machine safety requirements: Risk Assessment, Stop Time Measurements, Misapplied Mechanical Switches, Implementing Safety Categories, Series Connection for High-Risk Applications, and The Misconception of Collaborative Robots.

Download

the summary

View

webinar