SAFETY CONTROLLER WITH INTEGRATED AUXILIARY FUNCTIONS

MONITOR AXES EASILY AND SAFELY

Drive technology and the safety of machinery go hand in hand: in addition to an integrated solution encompassing safe drive systems and PLCs, safety mini-controllers like the Protect PSC1 from Schmersal also allow safety monitoring of drive-related parameters such as speed, acceleration, and position. Plus, thanks to communication modules, integration into the control and management level is straightforward, including with OPC UA if required.

Author: Dipl.-Ing. Christian Lumpe, Product Manager for Controllers, Schmersal Group

Source: DER KONSTRUKTEUR, Vereinigte Fachverlage, issue 2021/11-12

Download

technical article

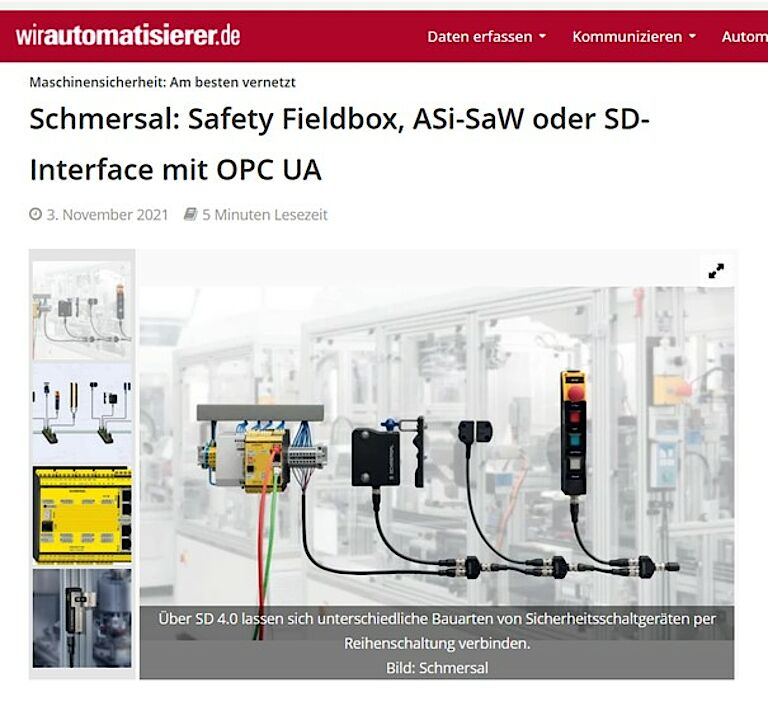

MACHINE SAFETY – BEST WHEN NETWORKED

SAFETY FIELDBOX, ASI-SAW, SD-INTERFACE AND OPC UA

Networking is a trend, in machine safety too. Electrical designers have various options at their disposal to allow safety switchgear devices to beconnected together – options that offer considerable benefit over traditional series connection. The solution that is most suitable depends on the individual requirements.

Author: Tobias Thiesmann, Systems and Solutions Manager, Schmersal Group

Source: www.wirautomatisierer.industrie.de, Konradin-Verlag, issue 11-2021

Download

technical article

Risk Assessment Methods For Machine Safety And Cobots

The executive summary from our webinar

Risk assessments are the starting point to any machine safeguarding initiative. Identifying the risks is the first step to abating them. But many individuals rely on their understanding of what equipment requires risk assessment or use a company standard that may not follow current applicable standards. This executive summary of our recent webinar explains methods for creating a risk assessment program for all EHS, engineering design, and maintenance staff in your company.

Download

technical article

View

webinar

INTEGRATED OR SEPARATE?

SAFE CONTROL TECHNOLOGY ON SMALLER MACHINERY

Safety controllers are becoming increasingly popular as an alternative to relay modules, even on smaller machinery. The designer can opt for one of two concepts: some designers favour integration of safety into the automation PLC, but a separate (small) safety controller offers clear benefits.

Authors: Christian Lumpe and Tobias Thiesmann, Product Manager for Control Systems, Schmersal Group

Source: SPS-Magazin, issue 06-2021

Download

technical article

INDUSTRIAL ROBOT PROTECTION

Alternatives to the Safety Fence

The choice of protective equipment around a robot workstation is made easier if one keeps a close eye on the individual circumstances.

Author: Tobias Thiesmann, System and Solutions Manager, Schmersal

Source: messtec drives Automation 8/2021 E, S. 7–9, Wiley-VCH GmbH

Download

technical article

Building A Machine Safety Mindset

The executive summary from our webinar

Many individuals involved in machine safety design rely on their understanding of “what is safe” when designing or upgrading an industrial machine. This can lead to inconsistent machine safety methodologies amongst EHS, Engineering design, and maintenance professionals in a workplace. This executive summary of our recent webinar discusses the steps of building a machine safety mindset to achieve a more uniform company machine guarding and safety methodology.

Download

technical article

View

webinar

Case Study: Practical Safety Solution For Setup Mode

Safety Evaluation Of A Redundant Rotary Encoder With Use Of A Safety Mini Controller

For setup mode or troubleshooting on machinery, the ‘Safely limited speed with opened guard door’ safety function is extremely relevant. This case study from Schmersal and Wachendorff presents an example safety solution involving a redundant rotary encoder and a safety controller and evaluates the solution in accordance with EN ISO 13849.

Download

Case Study

Sanitary And Hygienic Design Standards

An overview of US and Canadian standards for food industry

Hygiene and sanitation are key issues in the food processing industry to prevent food borne illnesses. It influences the design of machines used in areas that need to be constantly cleaned. It is important when selecting safety devices or command devices for food processing machines that they meet hygienic or sanitary standards.

Download

technical article

Challenges In Machine Safeguarding

The executive summary from our webinar

Companies understand that employee safety is critical. No business wants its workers to get injured. Despite this understanding, companies still seem to come up with numerous reasons why they can’t implement the very machine safeguarding solutions that would keep their employees safe. The challenges to machine safeguarding are significant, but these challenges can be overcome with proper education, good risk assessments, and solutions that are developed and implemented to meet the specific business need

Download

the summary

View

webinar

FAQ - How To Safeguard Your Robots and Robot Cells

Questions and answers on robot safeguarding

More and more robots are being introduced and utilized for industrial automation. From the traditional industrial robot to modern technology with collaborative robots, challenges arise to have people work safely on robots and in or around robot cells. Learn more about how to properly safeguard robots and robot cells in this Frequently Asked Questions (FAQ).